Implementation

Sizing Components

I figured I would be driving my circuit with two 18650 cells, so I decided to count on a 6V minimum input voltage and promote a 50% duty cycle as nominal. With a 6V input and 120V output, this works out to a 1:20 turns ratio.

The primary goal of sizing components in all DC-DC switchers is to keep your circuit in “continuous conduction mode” or CCM. CCM means that at all points in the cycle, current is either ramping up or ramping down. CCM makes it possible to keep your output relatively stable and also avoid situations where you potentially super saturate your inductor which will lead to energy losses.

Load Requirements

In order to size the output current requirements, I first needed some info on exactly what kind of load I was dealing with.

Update:

This post was originally written with an incorrect electrical model of my EL panel in mind. For the remainder of this discussion, all of my calculations are done for a resistive load of 56k

![]()

.

So it looks like my load is 56k

![]()

or .25W. I figured I’d round this up to 1W just to be safe.

CCM

So, sizing the inductor is kind of odd because you have ramp up coming from one coil and ramp down passing through another. To make things easier, we can just pretend that the transformer is actually an inductor. This is made especially easy because current is never passing through the primary and secondary winding at the same time. Looking at the primary and secondary current strictly from the perspective of how they contribute to the magnetic flux, we can do this:

![]()

Or, talking about the averages:

![]()

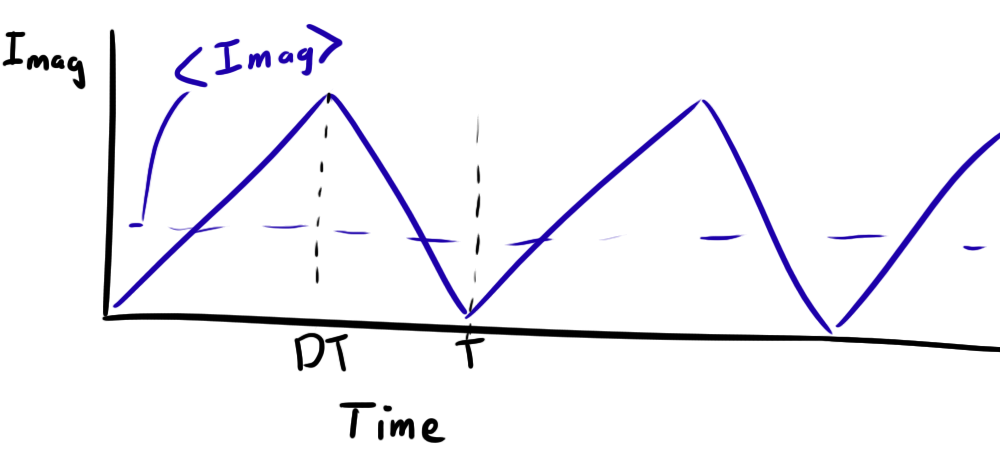

Calling our current the “Magnetization Current”. Let’s draw out this current as it ramps up and down:

So we have to size our inductor such that the peak of

![]()

isn’t too large and so that it never drops to zero. Remember from before that our current in the primary winding (and therefore all of

![]()

during the first part of the cycle) ramps up to:

![]()

While the switch is turned on. When the switch is turned off, it will then ramp down through the secondary winding. Assuming we’re staying in CCM, the switch should turn on again before this secondary current drops to zero. Thinking of a worst case, let’s consider that the current just barely hits the zero mark before restarting (like in my graph above). Under these conditions, the average of

![]()

will be half of the peak. We can do this:

![]()

We need to make sure the transformer is at least large enough to make the above true:

![]()

In the case of my 1W power draw at 120V output, I’ll have a 8.3mA secondary current which works out to:

![]()

.

In order to size my transformer, I first need to figure out how (and at what frequency) I’m driving it.

Driving the Transformer

Driving the transformer in a flyback circuit is kind of a difficult business. As mentioned before, the output voltage can fluctuate as load fluctuates, so it’s important to adjust the input duty cycle appropriately to keep the output voltage relatively constant. Additionally, a flyback converter is not a first-order system which means that adjusting the duty cycle will not immediately adjust the output voltage. There is a small delay there. Because of this, you can have some nasty oscillations in your output as your circuit keeps overshooting its target.

Rather than working my ass off to make a proper feedback system, I opted to use a pre made solution: the LT1425. It’s actually a pretty cool part. It pulls some black magic to determine when the transformer flux is close to zero and only turns on the switch when this is the case. In theory, this should prevent the output voltage from rising should the load resistance increase.

Now this probably wasn’t the best choice in drivers mostly because it’s designed specifically for systems with isolated secondary windings, and that’s a lot what you’re paying for. I grounded my secondary winding, so that feature is thrown out the window.

This part, if configured correctly, should keep my output voltage relatively steady. It regulates the voltage by altering the duty cycle and operates at a switching frequency of 285kHz.

Knowing this, I can properly size my inductor:

![]()

![]()

So as long as my primary winding inductance is greater than

![]()

I’ll be okay.

Now, keep in mind that the math I do on this blog is not necessarily the same math that I did during my initial design phase. For some reason, when I was sizing my components for my initial design, I was counting on a 100kHz switching frequency reaching my target voltage at a 75% duty cycle. This yields a required primary inductance of around 170

![]()

H. This answer isn’t wrong, it just gives me a much larger transformer than is really necessary. If I built this again, I would use a much smaller transformer to lower the size of the finished product. So from here on out just humor me…

![]()

Let Me See that Ripple

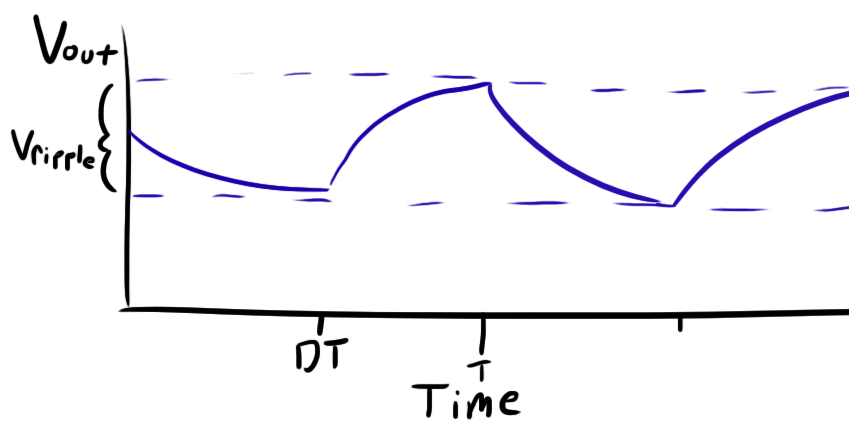

Seeing how a flyback converter only delivers charge to the load during part of every cycle, you can imagine how the output voltage wouldn’t be exactly steady. To prevent large ripples in the output voltage, you can add a capacitor in parallel with the load. As charge is delivered (while the primary winding switch is off), the capacitor voltage rises exponentially. When the switch is turned on again, the diode prevents charge from leaving the capacitor from the transformer side and it discharges exponentially through the load.

As you know from the formula:

![]()

A current source/load will cause the voltage to ramp up/down. Increasing the size of

![]()

will cause that ramp to be slower. Because the charge/discharge times are fixed by the switching frequency and duty cycle, the slower the voltage ramps up, the less dramatic the voltage ripple.

We can size how large this ripple is by considering the case where the capacitor is discharging. We know that our output current is 8.3mA from before, and we know that the discharge time will be based on the duty cycle and switching frequency. This allows us to size our capacitor using this formula:

![]()

![]()

So if you decide what your maximum voltage ripple (

![]()

)should be, you can decide on what your minimum capacitance should be. Let’s say maximum ripple that we can accept is 1V.

![]()

![]()

![]()

Because the currents are so small and the frequency is so high, you can get away with a pretty small capacitor. Unfortunately, this capacitor needs to be rated for 120+ volts.

Update

This is only true for resistive loads. For capacitive loads (like EL materials), check out this post.

yea there is a MUCH MUCH easier way to do this..

you take the standard inverter and the el panel and put a CDS photocell in series then take a standatd lm328 amplifier and hook the output to a bicolor LED and shine that on the photocell

DONE! i can give you schematics and stuff if you want

So you’re just talking about putting an adjustable resistance in series with the EL panel? I suppose that would work, but it’s not the most efficient way to do it.

Also, looking at a few datasheets, the maximum power dissipation though a CdS cell is around 100mW. If I were to use one on a panel, it might need to dissipate upwards of 7-800mW. It couldn’t take the heat. I suppose you could put a few in series, but that’s going to get pretty messy.

This solution might work in smaller loads like short EL wires though. Thanks for the tip!

When I first read your comment above I thought you were using the photocell to read the light from the EL panel and then reverse the voltage polarity when it detected maximum brightness, which should generate AC that would self-regulate to the right frequency to sustain that brightness level. But then when you mentioned LEDs you lost me! But would a feedback control mechanism like what I thought you meant actually work?

Matthew was recommending using a optoisolator as a variable resistance. The idea is that you could control current from a low-voltage circuit and not have to worry about the 120V blowing anything up.

You present an interesting idea, but I think it would end up being more trouble than it’s worth. The EL panel is a fairly “slow” material. It takes a few milliseconds for it to react to changes in current, so using its brightness in some kind of feedback system would prove difficult. To say nothing of the wiring/mechanical complications this would create.

>> I chose the 1N4148 which has a gate capacitance of just 4pF.

Not gate. Junction.

Since you were ordering from Digi-Key anyway, you could have purchased some BAT-41 Schottky diodes (19,000 in stock) . The BAT-41’s capacitance is 2pF, half of the 1N4148’s capacitance, and its forward voltage at 20mA forward current is 0.30 volts per diode, significantly less than the 1N4148’s 0.95 forward volts per diode.

Whoops, typo. Thanks.

I figured out my diode problem after I already made my order, so I had to use what I had on hand. Next time I’ll be sure to choose more wisely. Thanks for the tip!

while pouring over various patents on zinc sulfide phosphors i discovered reference to the color shift in el wire, my 555 based driver was a quick and dirty means of observing it myself and as an excuse to learn something about driving el wire… more of a first attempt using spare parts before devoting more time to designing a proper circuit rather than basing it off some simple dc to ac inverter circuit i found in the internet

along with the brightness being a function of frequency i found voltage had a similar effect but would cause the el wire to age faster than driving at a higher frequency would, and yes driving at higher voltages also caused my salvaged transformers to overheat and leak paraffin wax everywhere

Oh by all means, I think it’s great what you did, and it really helped me in my initial research! I was just making a point that in general, there aren’t too many resources available on EL wire and driving it properly.

there really arent, i had to resort to reading dozens of white papers and patents to figure everything out, my result was a working driver that was extremely inefficient, occasionally overheated and administered ~130 volt shocks when i wasn’t paying attention

ive also been working out some ideas on mixed frequency driving el wire to increase lifespan while making it brighter by rapidly switching between low and high frequencies at a rate where it would be brighter while impacting lifespan al little as possible

I also noticed the frequency shift.

Wonder if this effect can be used to make a variable spectrum microscope light?

For certain applications this would be handy indeed as if the wavelength shift is linear then you could image a sample at a range of multispectral frequencies rather than green or blue.

I like the Supertex HV852 for this as it draws under 5mA with small wires allowing a PIC to directly drive it and adjust frequency with a single drive lead and a capacitor.

So one 12F683 can run six separate EL wires, with Charlieplexing even more.

as far as i have observed there is only a single color shift at ~2000 hertz and i have not found any information to indicate there any more

it is far from linear and im not sure the amount of light would be sufficient for a microscope anyways

Pingback: Revisiting the EL Panel and the True Meaning of RMS | ch00ftech Industries

Pingback: Naw But Really Though…How Do You Power An EL Panel? | ch00ftech Industries

Pingback: I Should Give China More Credit | ch00ftech Industries

Pingback: The Color Mixing Christmas Light Project » Blog Archive » Pixel Mapping a Jogging Jacket

Pingback: Dimming EL Wire Dreamcatcher | ch00ftech Industries

Pingback: Sound Reactive EL Panel Dimmer (for real this time) | ch00ftech Industries

Pingback: Months of failure lead up to this EL panel dimmer that pulses to the music

Pingback: Months of failure lead up to this EL panel dimmer that pulses to the music | Daily IT News on

Pingback: Can I get this thing off my desk now? | ch00ftech Industries

Pingback: Soil Moisture Sensor | ch00ftech Industries

Pingback: More EL panel / el driver / el inverer hacking – pulsing | Reactive Lights

I found a great source for the EL panels. http://www.etsy.com/shop/lightkraft I looked all over and they are the least expensive in the US.. Most of their prices include the inverters (which are matched to each panel). Another good source is EL-WORKS http://www.el-w.com

Pingback: Bucking It Up » Geko Geek

https://ch00ftech.com/wp-content/uploads/2012/05/flyback11.png

Just saying, #schematicsthatlooklikefaces

What’s your take on this method?

http://www.enactiveenvironments.com/enabling/pwm-and-electroluminescent-smooth-dimming/

Hi,

How can I contact you? Email

Just click the email button at the top of the page!