While my Tindie QR Clock fundraiser is underway, I thought I’d take the opportunity to post an update on another project I’m working on.

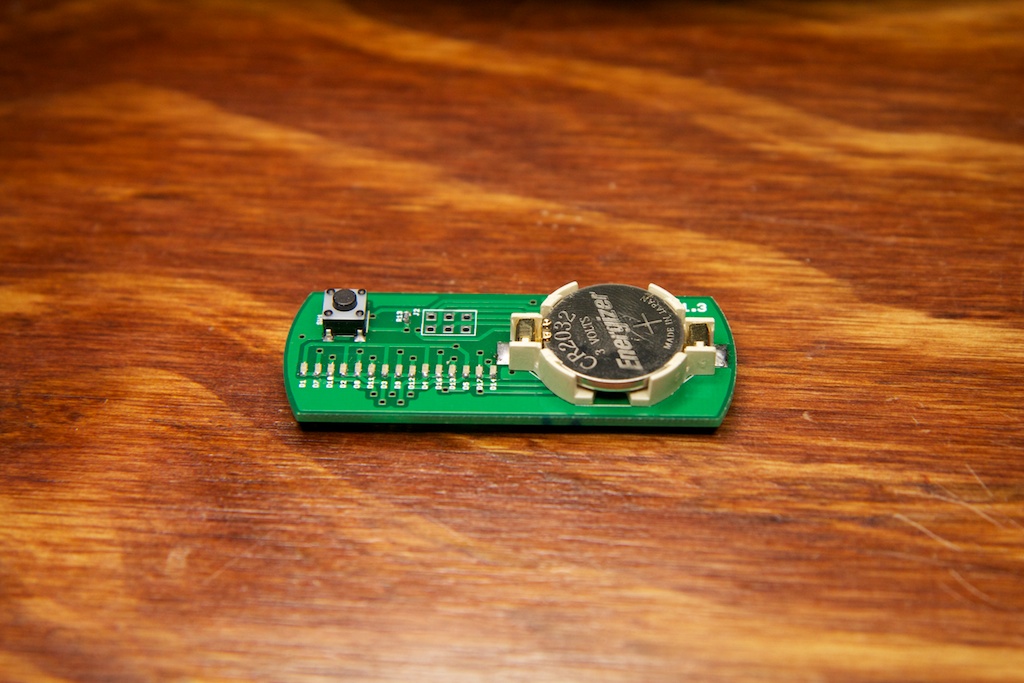

Remember this guy?

Reflecting on Reflectors

If you recall, the last time I talked about my longboard wheel display, I had pretty much given up on the whole concept. The main issue was providing an inexpensive and robust method for detecting the wheel’s velocity. I had previously tried using an IR reflection sensor which worked fairly well for a short demonstration.

The reflector was attached to the wheel’s axel and stayed stationary as the circuit board rotated around it (more detail/pictures in the other post). There were two main problems with this strategy. Firstly, the reflector was pretty far away from the proximity sensor. In order to successfully bounce an IR beam off the reflector and back into the sensor, I needed to boost the IR LED’s power by quite a bit. By the time I got it working, the LED was drawing about 15-20mA of current which rapidly killed the battery.

Secondly, the shape of the reflector didn’t really give me much leeway when it came to different wheel shapes/designs. Longboard wheels aren’t standard, and if I was hoping to make a universal display that fits all shapes, I wasn’t going to do it with that reflector scheme.

New Method

Shortly after I finished up writing that blog post, I went to see a movie. By the way, if you want to see a block buster movie on opening weekend, it helps to go alone. You show up 10 minutes before the movie starts and still get the best seat in the house.

Walking home, I turned my phone back on and noticed a new comment from reader MarkS. He suggested making a flange that stemmed outward in the direction of the axel. Such a device would work in virtually any wheel and could be easily modified to fit by the end user. The best part is that rather than being used as a reflector, it could actually be used as a beam-break. This would drastically reduce the amount of power required.

If you don’t quite understand what I’m describing, read on.

PCBs

Considering there was only a small change from my last design to accommodate a new sensor, there was very little different between my new PCB and the original one. I wasn’t too keen on the prospect of spending the afternoon etching exactly the same thing over again, so I opted to instead get the PCBs made this time.

Someone I met at a party (yes, I talk about Electrical Engineering at parties, shoot me) recommended I try out Seedstudios. They offer an incredibly cheap PCB printing service. They save money by combining multiple smaller orders into one big one that they ship off to a CM to print all at once.

What it means is that I got 10 fairly high quality PCBs for just  1-2 a piece for orders of over 100. That’s simply too much to add to what is otherwise a very low BOM cost.

1-2 a piece for orders of over 100. That’s simply too much to add to what is otherwise a very low BOM cost.

Looking Forward

So I’m already on the 3rd generation of this thing, and I’m still not satisfied with the solution, but I think I’m getting closer. On the original post, reader Derek Lewis left a comment suggesting that I try a Hall-effect or magnetic sensor and use a small magnet instead of a reflector or beam-break. I originally overlooked Hall-effect sensors as I assumed that they were too pricey, but after some research, I found some that were actually cheaper than my optical sensors!

Also, reddit user cypherpunks suggested that I change the current-limiting resistors of my LEDs to reduce the amount of light that the inner LEDs give off. Given that they won’t be moving as fast, they don’t need to be as bright. This could further increase the battery life of the light. I’ll have to roll that suggestion into the next revision.

I still have 9 more of these PCBs, so I might keep playing with different beam-break materials to see if I can increase the durability, but I’m still glad that I’ve got a few backup ideas anyway.

Hey, Why not give a slight crease to the aluminum along the entire length, down the middle. Much like they use on large metal panels. This would give strength and rigidity while still maintaining your other criteria. Or at least it should..

I agree with Derek on using a Hall Effect Sensor. You do have to select one very carefully as some don’t reset fast enough to be used with high RPM and some require the opposite magnetic pole to reset them.

For my POV spinner, I’m using a Honeywell SS351AT. I’m not sure what your price range is, but they’re $0.96 from Mouser.

How did you get the CR2032 to work? I tried one of those on my first spinner, but found that it only ran for a minute or two. After looking at the datasheet, I found that they’re generally designed to run with a nominal current draw of 0.2 mA. I had to switch my whole design to use bigger batteries to get it to run long enough even for me to debug.

Good advice. I’ll probably be ordering a few different kinds and kludging them into the other 9 PCBs I’ve got. For SOT-23 package, that shouldn’t be too hard.

CR2032s are designed to be used in wristwatches which is why their nominal draw is so low, but they can be driven much higher if you can stand a substantial voltage drop (bypass capacitance helps). I made a point of more or less starving my LEDs of current, and I’m only driving 5 at a time and multiplexing them. That helps cut down on the overall current draw.

You could stick with the beambreaker idea and change the shape of the flange to be more sturdy against vibration.

I am thinking about rolling the aluminium sheet with an opening on one side for the beam. If you roll it, you can affix it to the axle from different sides.

Of course it complicates the design so it is harder to make for the enduser himself. Plus i am not sure what an easy way of sticking the “ends” of the roll together would be.

But I guess you wouldn’t need to change anything else, hardware or firmware-wise.

why not make a loop out of thin clear plastic, you could colour in a strip with marker pen, this would block the sensor, and hopefully the clear plastic would not, the whole thing would be pulled through like a ribbon. It’s super lightweight, so hopefully even with a strong impact, the sensor shouldn’t be damaged.

I’ve considered something like that, and as simple as it is, it still requires some kind of manufacturing which I simply can’t do by myself. It’s sounding like I’m going to have to contact some plastic forming facilities for this project anyway, so if/when I do, I’ll be considering that design.