I’ve done a few commissioned pieces for artists and musicians on this blog, but I would like to make it clear that my primary objective is to provide educational content for my viewers and to also catalog my work for my own future reference.

Basically, I’d be happy to make something for you as long as it is sufficiently challenging, new, and interesting. The DJ Jacket and ongoing EL Panel shirt projects are examples of this.

If it would make an interesting blog post, I’m all about it. Unfortunately, I’ve gotten numerous requests for something that I don’t think would make a very interesting project/blog post, so I’m addressing it briefly here to help those who would like to make it for themselves.

Chris Who?

So, here are some emails and comments I’ve gotten over the past few months:

I’ve never been a big wrestling fan, so I decided to search around for who this Jericho guy is. Apparently his trademark is a light up leather jacket that he wears. I decided to search for similar jackets on Google…

Huh…well that explains a lot.

The Goal

Looking at his jacket, I realized that it’s basically just a bunch of white LEDs that blink in sequence. Electrically, this jacket is very simple, though I can’t speak for the logistical complications of wiring up that many LEDs through the sleeves without getting them tangled. I will be focusing exclusively on the electrical aspects, so if you want to make the jacket, I hope you can figure out all the sewing and rhinestones or whatever.

You might also want to hit the gym if you want to pull off a convincing Jericho…

This post will be directed towards a beginner audience. My hope is that everyone who wants a Jericho jacket can make one, but you might have to learn a few things first. This will not be a step-by step tutorial. You will need some rudimentary electronics knowledge and soldering skills to make this happen. There are numerous guides/helpful communities online that should be able to help you if you get stuck.

You will need to order some parts for this project. I will not tell you exactly which to order, but I will tell you what to look for and where to look. If you’re unsure about a part, order a few different ones. They’re all pretty cheap. For the same reason, always order more than you think you’ll need.

This circuit will be completed with simple 7400 logic chips and analog components. You won’t need a micro-controller for something this simple, so bring your Arduino back to the store and spend your money making 5 of these instead 😉

If you are seriously considering making this jacket, I recommend taking some time to try to fully understand what is going on. Draw out your own schematic and make some decisions before you place your parts order or start building.

The best tip I can offer you is to try to visualize the problems that will come up before they arise. This is the number one skill that makes a good engineer, and working on it now will help you out a lot in the future.

The second best tip I can offer is if you aren’t sure if it’ll work, try it anyway! The currents and voltages involved in this circuit are not high enough to hurt you, so the worst that can happen is that you blow up maybe $3 worth of parts.

It will probably be a frustrating process, but it will definitely be a very rewarding one.

Disclaimer: I am “blind-designing” this circuit, so I haven’t tested it before. Though it’s a fairly simple circuit, there is a non-zero chance that I made a mistake somewhere. If you’re having trouble with it, feel free to email me and I’ll see if I need to fix the post.

Looking Closer at Mr. Jericho

I wanted to get a closer look at Mr. Jericho’s jacket, so I took a look at this video on Youtube. Not exactly sure why his jacket is “trolling” him (and sorry for the music), but this did give me a very up-close view of his jacket during the awkward frames where he stands motionless (at around the 0:11 mark). I took some screenshots of the blinking sequence and assembled them here:

It looks to me like there are only 4 different blink stages of the LEDs on his jacket. After the fourth stage, it restarts back at the beginning. Presumably, all of the LEDs lit during any particular stage are all wired up to the same point in the circuit.

So all we need is a circuit that can power four different groups of LEDs that each have maybe 10-20 LEDs per group.

Subsystems

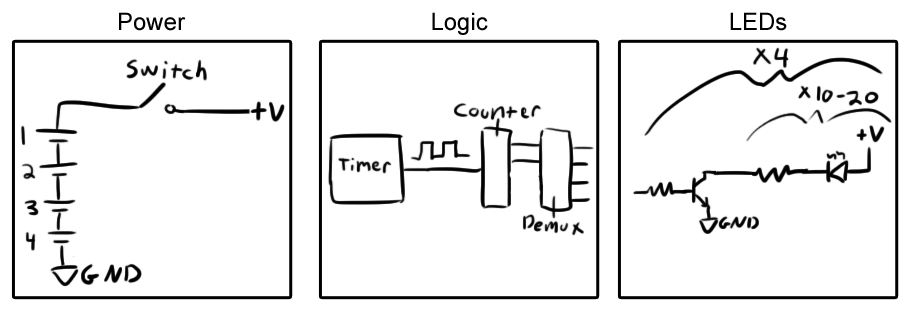

So, like any good electronic circuit, there are a number of different subsystems that all operate independently, yet work together. It’s easiest to explain the circuit by explaining each of the parts independently. The sections of this circuit are as follows:

So let’s get started!

Power

So, you have a few options for power. Obviously, you’re going to want it to be battery powered (so you can run around the ring and body slam people without an extension cord…or whatever), so the question is “what kind of battery?”

There are three things you need to consider when choosing a battery supply:

- Voltage

- Current

- Energy capacity

Voltage

Voltage is something that is set by the battery itself. Conventional alkaline batteries (AA, AAA, D, C, etc) are usually 1.5V (though they can start at around 1.7V and drop to 1V or so as they become depleted). Li-ion batteries are nominally around 3.7V or so (starting at 4.2 and dropping no lower than 3).

Current

Current is determined by what’s going on in your circuit. Basically, the battery will have a maximum current rating, but the amount of current that it’s actually sourcing at any given moment depends on the load that your circuit presents.

Think of it this way: your wall socket is sourcing 120V to everything you plug in, but your phone charger is probably going to be using much less current than something like a hairdryer.

Typically, Li-ion batteries can source a lot more current (a number of Amps) than similarly sized alkaline batteries (maybe 3-400mA).

Energy capacity

The last thing you need to look at is energy capacity. Energy capacity will tell you the approximate battery life of your circuit. It is typically measured in mAH which stands for “milliamp hours”. This is a measure of how long your battery can supply a given current.

If your battery is rated for 1000mAH, it means that it can supply 1mA for 1000 hours or 1000mA for 1 hour, etc. Note though that your mAH rating is not exactly constant. For example, you probably couldn’t supply 100,000mA for .01H. Capacity will drop as current draw increases. You can find mAH ratings on the side of some batteries, but for others, you have to look at data sheets online.

Picking a Battery Pack

I’m going to go ahead and recommend that you stick to alkaline batteries for this project. They won’t last quite as long as a similar Li-ion battery, but they’re a lot easier to deal with for beginners.

As you will find later, you need at least 4-5V or so, so you’re going to need to run some batteries in series. Putting batteries in series adds their voltages together, so putting 3 alkaline batteries in series will give you (

![]()

) 4.5V. As your batteries die though, your voltage will drop, so it’s probably best to overshoot and put four in series giving you a nominal 6V.

Your current draw depends on how you configure your LEDs and how many you have. Given that you will be working with white LEDs and a 6V power supply, you will see later that your LEDs will draw about 20mA a piece, and that’s only for the ones that are on at a given time. If you want to have 20 LEDs on during each blink stage, you will need

![]()

.4 Amperes of current. You need to make sure whatever battery you choose can handle that kind of current draw.

I recommend looking at the data sheets that Energizer offer on their site. Using this info, you should be able to determine whether four AAAs are going to cut it or if you need to step-up to C or D cells.

Some sources will tell you to put batteries in parallel to increase current capacity, but I don’t recommended it. If one of your batteries is already partially discharged, your other parallel cells could discharge into it which will severely decrease the battery life of your circuit.

Shopping tips

- You will need some kind of battery holder. I recommend shopping around on Digikey. Here’s a link to their battery holder selection.

- You might also want to pick up a power switch. I recommend an SPST non-momentary switch. Just make sure it’s rated for your current draw.

LEDs

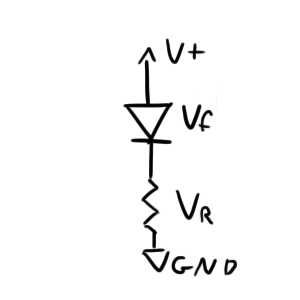

Wiring LEDs is a very simple process that seems to trip up a lot of people. Basically, you just need to know your source voltage, LED forward voltage, and nominal LED current.

We already know the first one: 6V, and I’ll let you know that nominal LED current is typically 20mA for conventional LEDs (it can be a lot higher for high-power LEDs used in home/automotive lighting applications).

So what about the forward voltage? This value is usually represented by the symbol

![]()

and varies depending primarily on the color of the LED. See, the forward voltage determines how energetic the photons are as they leave the LED. Lower energy photons are of a lower frequency and therefore are emitted out of an LED with a smaller

![]()

. This is why red LEDs typically have

![]()

in the 2V range and blue LEDs are usually around 3.5V.

So where does white fall? White is the sum of all the visible light frequencies! As it turns out, manufacturers create white LEDs by first creating blue LEDs and then coating them with a special phosphor that lights up yellowish. The blue and the yellow together create white. So from an electrical standpoint, we’re basically just lighting up blue LEDs (this is why I said we needed a supply voltage in the 4-5V range before).

Limiting current

LEDs (like all diodes) are kind of funny in that the voltage drop across them will be constant. This means that no current will flow through a blue LED (and it won’t light up) until you have at least 3.5V across it. It also means that if you put more than 3.5V across it, it will draw way more current than it can handle and explode.

For this reason, we will need a resistor in series to limit the amount of current our LED draws. Here’s a simple schematic:

Where

![]()

is locked at 3.5V and

![]()

is the voltage drop across our resistor which follows Ohm’s law:

![]()

Where

![]()

is the current through the resistor and

![]()

is its resistance (measured in Ohms).

![]()

and

![]()

must add up to

![]()

which is the voltage of your power supply and is considered constant for our purposes. You can see how this resistor helps limit the current. If

![]()

ever went above 3.5V, more current would flow which would cause

![]()

to increase. Because the sum is constant (equal to

![]()

),

![]()

would have to decrease to compensate.

This will result in the voltage across the diode being held at exactly its rated

![]()

.

Now, it’s still important to choose this resistor value wisely. It’s great that you’re limiting the current, but if you’re limiting it to a value that is still above the rated maximum current through your LED, you’re still going to blow it up. Looking at a number of LEDs, you’ll find that a typical current rating is something like 20mA.

To limit your current to 20mA, you just need to run your Ohm’s law in reverse:

![]()

Where V is

![]()

and I is 20mA. Note that

![]()

will be whatever the difference is between

![]()

and the

![]()

of your LED.

Now, it’s unfortunate in this case because if your rail is around 6V and

![]()

is 3.5V, you’ll be dropping something like 2.5V across your resistor. It’s going to be eating up a lot of power in that configuration (power = voltage

![]()

current). Ideally, the voltage drop across your resistor should be as close to zero as possible so that all of the energy is dissipated through the LED as light rather than through the resistor as heat.

You could try to lower your rail voltage by removing a battery, but then with your nominal voltage at just 4.5V, you risk dropping below

![]()

as your batteries deplete which would cause your LEDs to turn off before your batteries are all the way dead.

It’s also possible to boost efficiency in these scenarios by having two LEDs in series. In this case you would add the

![]()

s together and follow the same rules as above. Your “meta

![]()

” would be 7V which means you’d need more batteries in series to pull it off.

Or you could just leave it be. However you choose to handle it is up to you.

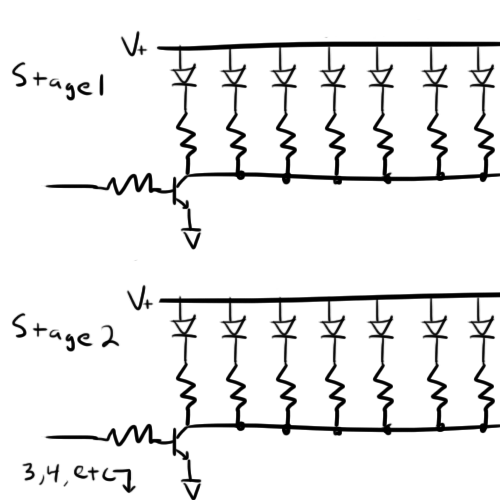

Controlling LEDs

Each strand of LEDs will be drawing somewhere around 200-400mA which is quite a substantial amount. You will need something to sit between your LEDs and your blinking control circuitry that can handle the current and be controlled by your low-power control signals.

To achieve this, we will use transistors that will switch LED current on and off. For this, I recommend NPN bipolar junction transistors (BJTs). There are about a billion NPN transistors to choose from, so I’m going to save you some trouble and recommend the 2N4401. It’s rated for 500mA of continuous current, so if you find that you need more than that, I recommend splitting your LEDs into two or more groups and running each group through a separate transistor.

You will need to configure your transistors like this:

Where the top half of the circuit is your LED and resistor from before. BJTs always act as a kind of current amplifier. The current from their collector to emitter will be some multiple of the current from their base to emitter. In the case of the 2N4401, the “DC Current Gain” can be anywhere between 20 and 300 as listed on the table on page two of the data sheet I linked to.

A BJT can sometimes be used to limit current from collector to emitter by limiting current from base to emitter. Because we’re limiting our current with our resistors, we just need to make sure that our base-emitter current is high enough to push the transistor into “saturation” where it won’t limit the collector current at all.

To choose the base-emitter current, first decide how much collector-emitter current you need this BJT to handle (maybe around .4A?). Then assume the worst-case for your DC current gain (20 as seen in the table on page 2). Now, you want your base-emitter current to be at least 1/20th of your collector current.

Setting the base-emitter current is achieved with

![]()

in a very similar fashion to what we did for the LEDs. The internal connection between base and emitter is kind of like the LED problem we discussed before, but its

![]()

is around 1V (you can see this under “Base-Emitter Saturation Voltage” on the data sheet).

If you do this correctly, when

![]()

is connected to

![]()

, the voltage drop from collector to emitter will be very close to zero, and the collector will be at nearly ground potential.

Putting it all together

Your whole set of LEDs will look something like this:

ASSEMBLY tips

- The orientation of the base, emitter, and collector pins of the BJT are outlined on the data sheet.

- With LEDs, typically the shorter lead is the “cathode” which is the part you want facing towards ground (towards the BJT).

- To help with wiring, it’s probably best to just run two lines up each sleeve for each “stage”: one for

![Rendered by QuickLaTeX.com \[V_+\]](https://ch00ftech.com/wp-content/ql-cache/quicklatex.com-ade01250e20cc9cff9c24d8ca5a0ce3f_l3.png)

and one for your BJT connection. You can then place all the LED+resistor pairs for that stage in parallel across those lines. Say, you might actually be able to have all four stages share the same

![Rendered by QuickLaTeX.com \[V_+\]](https://ch00ftech.com/wp-content/ql-cache/quicklatex.com-ade01250e20cc9cff9c24d8ca5a0ce3f_l3.png)

line, no?

Shopping tips

- You can shop for your white LEDs here. Just make sure to specify “white” as the color and “through hole” as the “mounting type”.

- For wire, I recommend stranded wire of around 24AWG. It will provide a good mix of current capacity and flexibility. Remember that higher AWG is thinner wire. You can shop for wire here.

- When shopping for resistors, you will probably want 1/4 watt, 5% tolerance, through-hole resistors. You can find resistors in basically any value you’d want, but it’s best if you stick to a standard values.

Control

So lastly is the logic to control all of these LEDs. This will be the most confusing part of this write up, so strap in.

This stage will utilize a pair of parts from the 7400 logic series. 7400 series logic is basically a classification for a wide variety of parts that all have similar electrical properties. This spec has been around forever, and a lot of the parts are no longer used. For those that are still in use though, they can be obtained from a large number of manufacturers in a large number of form factors.

7400 series logic parts all have part numbers that start with 74 followed by some electrical classification. For our purposes, we will be using the HC classification as it allows for a voltage rail from 2-6V. The low minimum input voltage will be important as your batteries die down. Note that if you chose to increase your voltage rail earlier, you’ll need to find some way to regulate the voltage going to your logic circuits to prevent from going over the 6V maximum rating.

The logic portion will consist of two parts:

- Clock that controls the speed

- Logic that controls the sequence

Clock

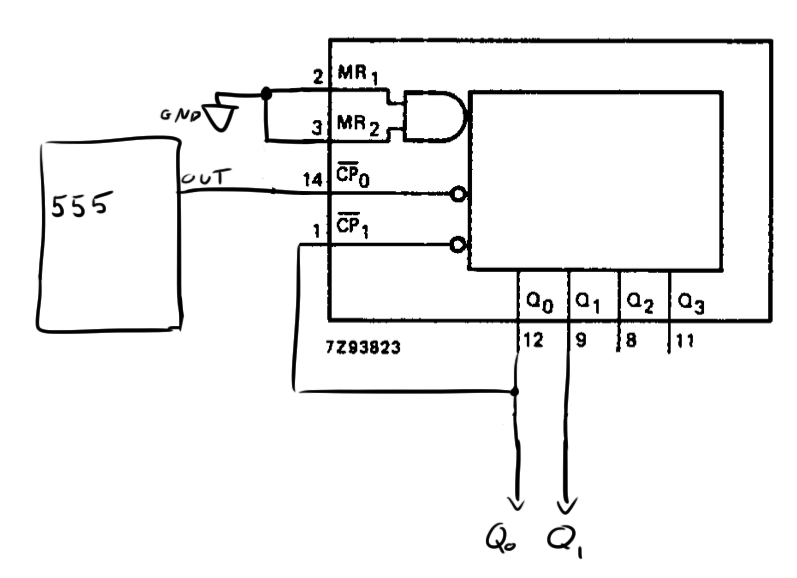

The clock will determine how fast the jacket blinks. To generate our clock pulse, we will be using a 555 timer (part number LM555). A 555 timer is a fairly simple yet versatile electronic component. We will be using it in its “astable” mode.

In astable mode, the 555 timer will output a square wave at a certain frequency governed by the components connected to it, and this frequency will determine how quickly the LEDs blink.

You can see from the Wikipedia article how to set the frequency. It looks like Jericho’s jacket changes LED stages about four times a second, so you might want to set your components for a 4Hz output frequency. It’s convenient that all 555 timers have the same pinout as you can use the pin labels in the Wikipedia article.

The “out” pin is going to connect to the input of your logic.

Logic

Now here’s the “special sauce” of this whole circuit. It’s the most complicated part, so I’ll take it slow. The first thing we will need is a part that can count to four and reset back to 1 instead of going to 5. To save confusion later, it’ll be easier if you think of it starting at zero and counting to three. We will start by first counting in binary and then converting that binary into something that will control our LEDs right.

This is a perfect application for the 74HC93 ripple counter. A ripple counter basically counts clock pulses in binary. Every time the input clock goes from a high to low value, the counter increments by one. This is a 4-bit counter which means it can count up to 15 (starts at zero and there are 16 different outputs possible). The four bits of binary are output on the four output pins labeled

![]()

.

Now, there’s something odd about the 7493. It has two clock inputs. The first clock pin

![]()

feeds the first bit of the counter while the other pin (

![]()

) feeds all the others. This makes the part slightly more versatile for reasons that I won’t get into. To “fix” this odd split-clock business, just connect

![]()

to

![]()

.

So with

![]()

connected to

![]()

, you’ll get binary counting sequence on your outputs that will increment with every high-to-low transition on the input. The only issue is that this sequence will count all the way from 0 to 15!

If you pay close attention though, you’ll note that we don’t actually have to worry about this. If we simply don’t connect

![]()

and

![]()

to anything, the output will look just like a 2-bit counter that counts from 0 to 3 and repeats:

| Q3 | Q2 | Q1 | Q0 | Decimal |

| 0 | 0 | 0 | ||

| 0 | 1 | 1 | ||

| 1 | 0 | 2 | ||

| 1 | 1 | 3 | ||

| 0 | 0 | 0 | ||

| 0 | 1 | 1 | ||

| 1 | 0 | 2 | ||

| 1 | 1 | 3 | ||

| 0 | 0 | 0 | ||

| 0 | 1 | 1 | ||

| 1 | 0 | 2 | ||

| 1 | 1 | 3 | ||

| 0 | 0 | 0 | ||

| 0 | 1 | 1 | ||

| 1 | 0 | 2 | ||

| 1 | 1 | 3 |

The best part is that after it reaches 1111, the counter will restart back at 0000 automatically!

Here’s a doodle of all the connections so far using a graphic from Fig. 4 of the data sheet I linked to above:

Note the MR connections. MR stands for “Master Reset” and will reset your counter if both pins are pulled high. For safety, it’s best to pull them both to ground.

Ok, so we’re almost there. With this setup, we’ll get two output pins that count up in binary from 0 and reset after they reach 3. Now we need something to take that and give us four output pins where only one pin is high at a time. What we need is a demultiplexer!

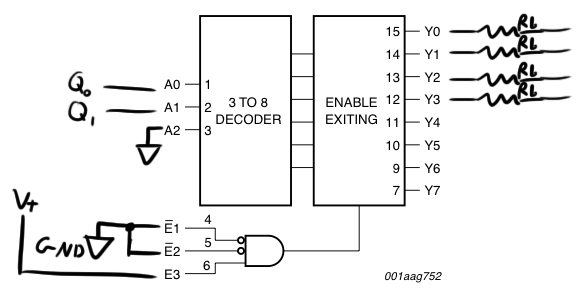

For this I recommend the 74HC238. This part is a “3 to 8” demultiplexer which means that it takes three binary inputs and has eight demultiplexed outputs. We won’t be using the third input pin though.

This part is kind of funny in that it has some “enable” pins to worry about. Basically, to “turn on” the part, you must connect the enable pins the right way.

![]()

and

![]()

must be connected to ground (the bar over the name means that it is “active low”) and

![]()

must be connected to

![]()

.

After this, you just connect your two input lines to

![]()

and

![]()

appropriately and connect

![]()

through

![]()

to the base resistors of your LED array. If you’re curious about what exactly will be happening, take a look at Table 3 on the data sheet.

![]()

and

![]()

follow what we have coming out of our binary counter, and

![]()

through

![]()

are what we need to go to our LEDs.

Here’s a doodle of the 74238 connections using Fig. 1 from the data sheet:

Note that it’s important to tie

![]()

to GND. Failing to tie it to anything will cause that input to “float” around and flip between a high and low input unexpectedly causing erratic circuit behavior.

Assembly tips

- Keep an eye on your pinouts and make sure you’re connecting the power and ground pins correctly.

- Logic chips can sometimes act unexpectedly if their power lines fluctuate a lot. To prevent fluctuations, it’s a good idea to connect a capacitor (maybe .1

![Rendered by QuickLaTeX.com \[\mu\]](https://ch00ftech.com/wp-content/ql-cache/quicklatex.com-bee17ce5c29d6fa9fa02b47a477d5c06_l3.png)

F value) across the voltage rails of your logic chips as physically close to the chips as possible. We call this a “bypass capacitor.” If your circuit acts erratically, your first reaction should be to check to make sure you included bypass capacitors.

- The pinouts of all the chips should be drawn on their respective data sheets. Note that almost all chips follow a similar number scheme with pin 1 starting near the top and the sequence wrapping around counter-clockwise. It’ll be useful to get comfortable with this numbering scheme.

- ICs like these can be very sensitive to the heat from your soldering iron. For this reason, it might be a good idea to purchase some IC sockets to solder. The socket itself is just plastic and metal which is very heat resistant and once it is soldered in, you can install your IC easily with no heat.

Shopping Tips

- Remember that as long as the part numbers are the same, the manufacturer doesn’t matter for 7400 logic parts.

- As you shop, remember that because you’re probably doing a through-hole construction, you need a “DIP” or “Dual In-line Package” for your “Package/Case”. This name is usually preceded by a number which is the number of pins of that particular package. Your IC sockets if you choose to use them, will have the same package types.

- You can find IC sockets here. Note that you want DIP with .1″ spacing. .1″ is standard for most breadboards and through-hole components.

- For small value capacitors, shop for ceramics whereas larger values might require aluminum electrolytic. Just pay attention to the capacitor polarity if you choose the second.

General tips

- It might be a good idea to try this all out on a breadboard before moving to solder. You can get breadboard kits and breadboard wire online for fairly cheap.

- Test a portion of the circuit before assembling the whole thing. If you don’t have an oscilloscope or voltmeter, think of how you could use an LED as a simple test indicator. Most LEDs won’t explode immediately if you run too much current through them for a short time.

Conclusion

So there you have it folks. How to make your own Chris Jericho jacket. Now get out there and start kicking ass! (and stop emailing me)

can u make me chris jericho led jacket/?

Pingback: Transistor Clock Part 3: Binary Counter and 7-segment Decoder | ch00ftech Industries

Make one & sell it to me. whatever the price.

$20,000.

My standard rate.

Search on facebook ” CHRIS JERICHO FANCY JACKET 2012″ THAT MAN MAKES THE JACKET. AND SELLS IT CHEAP

Hi I want to know what type of led lights those are , if they have a special name thank you

White. Through hole. Probably 3mm.

hay can u make me a cris jeriko jaket????/

https://www.facebook.com/ChrisJerichoFancyJackets

Bought one from him and never got it. Don’t order from the Facebook guy

Pingback: Finally, party lights | ch00ftech Industries

https://www.facebook.com/ChrisJerichoFancyJackets

this website, shows they have jericho’s jackets, and yes they sell.

It’s a scam. You send them money overseas via Western Union, and you never get a jacket. I learned the hard way.

can you please make this on PROTEUS PROFESSIONAL 7 please it will help me a lots !