So, I finally figured out what the deal was with my accelerometer needing to be asked twice what the value was.

As it turns out, I wasn’t actually giving the chip time to reply. I thought the micro would automatically handle receiving the data value, so I all I had to do was send the ACK at the end. In fact, the command that sends the ACK actually tells the micro controller to wait until the entire data byte has been transmitted, and then transmits the ACK.

So, when I was storing the value before sending the ACK, I was storing the value that I originally had in the register (the address of the accelerometer chip) and then waiting for the data and finally sending the ACK. Now, I’ve changed it so that it waits for the data and sends the ACK before storing the data value in the register.

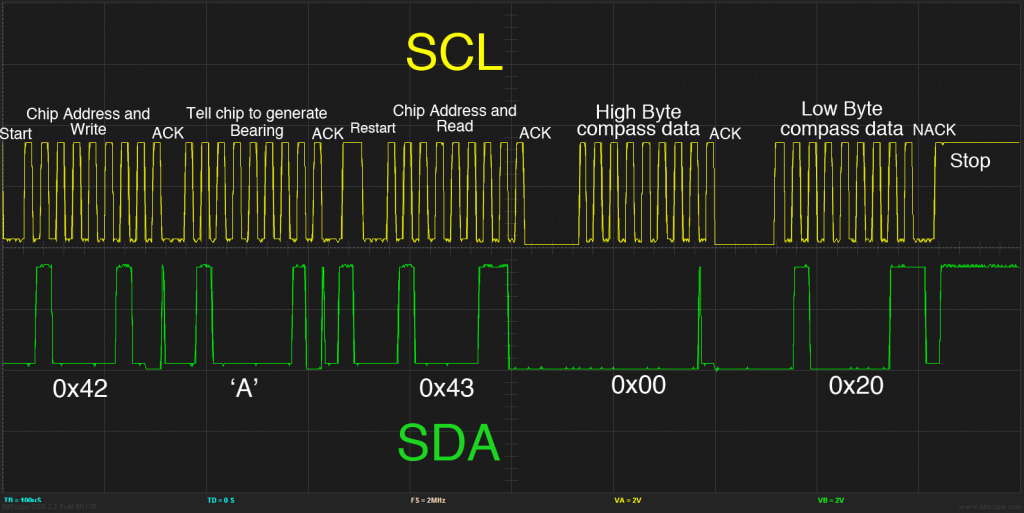

How did I figure all of this out? With an O-scope! I simply modified my code so that it would give me a voltage spike on one of the output pins while it was reading the data from the register. What I noticed was that it was spiking before it was supposed to. Here’s an example of what I mean: