After three months of work, it’s finally done!

Background

About a year and a half ago, I decided that I wanted to branch out from the fairly limited world of low-power 8-bit AVR microcontrollers into something better. Very few consumer products are made with such antiquated technology, and I figured that moving up to something like a 32-bit ARM processor would open a lot of doors for my projects.

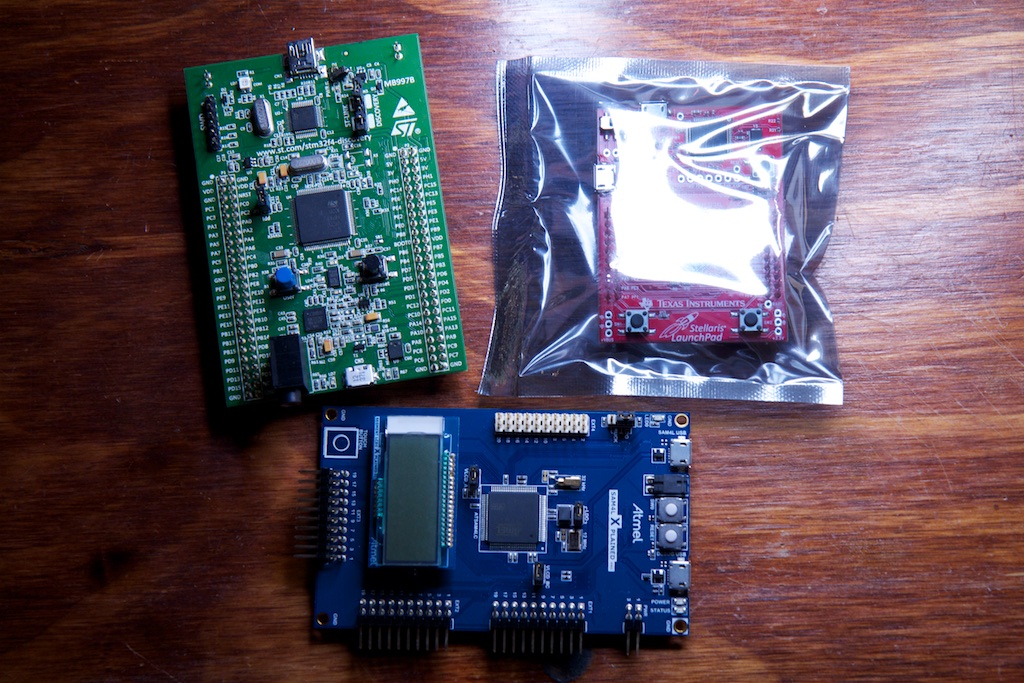

I quickly ran out and purchased development kits from three major ARM processor manufacturers.

Judging from the fact that the TI LaunchPad Evaluation kit is still wrapped in plastic, you might guess that I haven’t gotten a lot of use out of these.

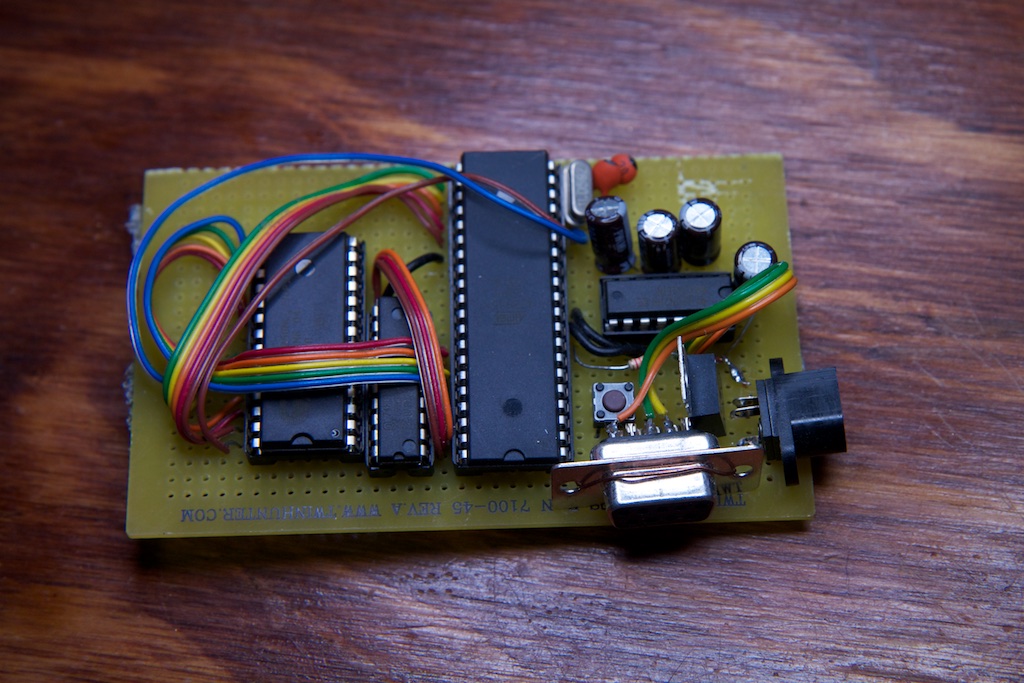

All of my projects so far have been either entirely analog or “bare-metal” C compiled with AVRGCC and programmed using AVRDUDE. AVRs are simple processors with a limited number of peripherals. As such, my code usually speaks directly to the special function registers of the part by manually modifying specific bits to turn on the ADC or start a timer.

As processors get more complicated, doing all of this special programming by hand becomes overly cumbersome especially considering that some simple tasks require multiple operations that must be performed in a certain order and in some cases within certain timing constraints. Each development kit came with a whole body of software that contains special functions to manage a lot of these operations for you.

Up to this point, I had been accustomed to keeping my entire project code inside a single main.c file. This is a horrible strategy for software development as it makes code very difficult to maintain, but I’ve never considered myself a software developer and it’s always worked for me. I started my life as a firmware developer by writing assembly code for the 8051; In fact, I didn’t even know what an AVR was until after I started working on my first pre-ch00ftech attempt at a persistence of vision display. What a mess.

Though programming in C has made my life about 1000 times easier, I’ve always liked that with assembly, you have 100% control over of the processor and can predict and account for its every action. As machine code gets covered up with more and more layers of abstraction, I tend to get a little anxious and have thus avoided using other people’s libraries for far longer than I should have.

This “bare-metal” coding strategy was no longer going to work for these more complex ARM processors, but when trying to incorporate their libraries into my little scripts, I got overwhelmed and eventually gave up. Reading a software library is a lot like reading a schematic. There is a general way things are supposed to be, and when you have zero familiarity with these standards, it makes it very easy to get lost.

For example, at one point I might have written:

return GPIO_ReadInputDataBit(GPIOB,4);

When I should have written:

return GPIO_ReadInputDataBit(GPIOB,GPIO_Pin_4);

Which caused some odd behavior since this line is present in stm32f10x_gpio.h

#define GPIO_Pin_4 ((uint16_t)0x0010) /*!< Pin 4 selected */

I generally learn best when a project is 90% stuff I know how to do and 10% new stuff, but this task had the percentages flipped the other way around and even with all of the documentation, I got lost pretty fast. Besides, I’ve never found it easy to just pick up and learn a topic unless there’s a specific reason for learning it. That reason didn’t come for another year.

Thermal Printers and Instant Cameras

While waiting at Nordstrom for my newly hemmed jeans to get rung up, I noticed how fast their thermal receipt printers print. Thermal printers don’t use ink but instead use a special paper that turns black when heated. As the paper is rolled out, a row of tiny heaters “burns” tiny dots in the page that can be organized to make up text. As a result, they have a very small number of moving parts. Usually, it’s just the feed motor and sometimes a paper cutter.

A few years ago, I saw an ad for a internet-connected thermal printer called Little Printer which I still think is a brilliant product if only it had better content for US customers (and cost about $100 less). There’s something innately fun about having a paper copy of something trivial like the weather forecast or the “word of the day” when everything has been moved online. Despite the short shelf-life of thermal printed text, having a physical copy in front of you gives you a certain sense of permanence and with the digital world so well organized, it’s much easier to accidentally stumble across physical keepsakes that may be strewn about in the real world.

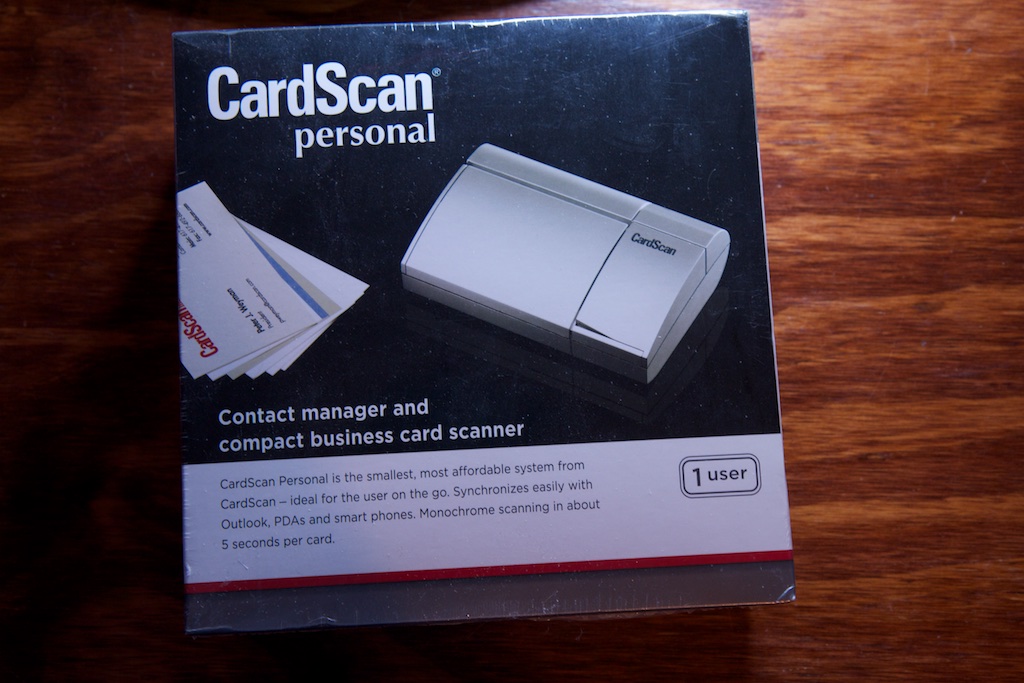

Wanting to do something with a thermal printer, I immediately started thinking up ideas. My first idea was…some kind of scanner thing? I guess? It was supposed to be a little motorized car that would roll across a document while scanning it in, and then thermally print out a copy of that document over top. I have no idea why I thought this would be a good idea, but that didn’t stop me from spending $50 on this which I still haven’t even unwrapped:

I think my confidence was still a little inflated from reverse engineering a children’s toy, and I thought that it would be trivial to do the same for a high-speed, full-color, proprietary scan head. Regardless, something must have come up because I never did order a thermal printer.

Fast-forward three years. I’m waiting at Nordstrom and it hits me. I should just make a camera!

Instant-photos managed to stay a part of popular culture from the 50s up until about the mid 2000s when the instant feedback and low-cost of digital cameras made them the new de-facto standard for sharing memories without a trip to the 1-Hour Photo.

The reality is that instant photos have always been terrible and it’s a miracle they lasted as long as they did. Polaroid film was extremely expensive, the printed images were small, the picture quality was terrible, the cameras bulky, and you still had to wait a few minutes to see if your picture came out at all.

In its death-throes, Polaroid released the I-Zone camera which took even crappier, smaller pictures and had an annoying length of tape on either end of the picture that was larger than the image itself.

Regardless, Polaroid was fairly successful for a very long time. I suppose the point is that people are willing to go a long way to get instant photos, and apparently image quality and size is not high on the requirements list.

This theme has persisted into the digital realm as well. The quality of a photo is almost irrelevant to a majority of the point-and-shoot population. Many pictures aren’t meant to adorn the halls of an art museum; they’re just an aid to help unlock a specific memory. The Facebook comments under the picture are almost as important as the image itself. I’ve seen people post phone screenshots to Instagram because it was easier than actually downloading and saving the image they were looking at. That 0.8MP version of that 8MP image is “good enough” so why bother use anything better?

Here’s a Polaroid picture of me on the first day I soloed when I was working on my private pilot’s license:

It’s blurry, the colors are washed out, and the image itself is pretty small. But who cares? A higher resolution picture won’t tell you that I was nervous as hell and sang “Bang on the Drum All Day” the entire time I was in the air while secretly fearing that I was somehow accidentally holding down the transmit button and doing impromptu karaoke to the entire airport.

The real issue with Polaroid has never been image quality, it’s been price. I remember feeling very nervous when using a Polaroid camera as each press of the shutter was another $2-3 spent. It’s almost as if the apprehension associated with the price tag was directly at-odds with the spontaneity of instant images in general.

So while eating a club sandwich in the Nordstrom Grill, I thought it might be cool to take both of these issues to their extremes. Make a camera the produces extremely low quality instant images for an extremely low price. You still get the novelty and benefits of a physical keepsake, and as long as the pictures are somewhat recognizable, they still serve the purpose of helping you catalog and recall memories.

Conveniently, Christmas is coming up, and this is the perfect gift for my sister who has made a hobby of working with novelty toy cameras. They don’t take super amazing pictures, but they have a bunch of really neat lenses that let you do things like extend the image frame to cover the sprocket holes or shoot 120 film. Here’s a roll that we developed together:

It’s some buildings and clouds in Korea.

So the task was to produce a portable camera that can print images instantly using an optical module and a thermal printer. Of course, processing a decent image quickly requires far more processing power than what’s available in an 8-bit AVR, so unless I wanted my instant-pictures to take weeks, this was the perfect project to get me started on ARM.

Pingback: Towards More Interesting Instant Cameras | Hackaday

Pingback: Towards More Interesting Instant Cameras - Tech key | Techzone | Tech data

Pingback: Towards More Interesting Instant Cameras | Ad Pub

Pingback: Towards More Interesting Instant Cameras | Hack The Planet

Pingback: Towards More Interesting Instant Cameras | 0-HACK

Thoughts about heading toward a KS project:

1. Separate the battery/charger from the camera/printer: Support attached and/or detached/cabled power, with standard LiPO standard and the option of a pack with replaceable/rechargeable NiMH cells (dirt cheap). Then, also offer the camera without a battery pack (DIY power is relatively easy if the interface is simple).

2. Personally, I’d want a clear case with all the internals visible, using standoffs and 3D-printed brackets where needed. Hopefully, this would also be the simplest/cheapest case.

3. Kit the custom parts and include a simple “no-solder” BOM for the rest. This permits a “partial gift” for the makers among us. And I certainly don’t mind giving Adafruit some business, especially if a small discount can be negotiated for this project’s BOM.

I think the above can provide a wider range of KS options and price levels with (hopefully) relatively little change to the core device.

Pingback: PrintSnap Wants to Bring Back the Instant Picture Using Dirt Cheap Receipt Paper

Hey there, I think this might interest you: http://www.sciencedaily.com/releases/2014/10/141022143628.htm

Yep, I’m well aware of that problem. I wash my hands compulsively anyway, and I’m sure someone will come around with a BPA-free option soon in response to public outcry. The same thing happened with Nalgene and leaded gasoline.

I want this! I want this soooo bad. Please sell me the first one!

Pingback: PrintSnap Wants to Bring Back the Instant Picture Using Dirt Cheap Receipt Paper - news from Allwebsolutions.net

When this becomes available, make sure it can be sent to Australia!!!!

Pingback: l’appareil photo instantanée le plus économique | news-apple

Hi Ch00f,

Your PA15 pin isn’t busted; the problem is that it is by default mapped as a JTAG debug pin and not to the GPIO block. In the device datasheet (the 100-page thing, NOT the 1000-page reference manual), there will be a “pin definitions” table near the front containing pin numbers for all the different package options, pin names (“PA15”), pin-types (“I/O”) and 5V-tolerance (“FT”), a “Main Function” column (this is the important part) and “Alternate Function” columns.

Note that for most GPIOs, the Main Function is GPIO, i.e. at power-on, PC12 is PC12, etc. However at power-on, PA15 is JTDI (jtag data in). This is necessary so that JTAG can start talking to a device when it boots. If you’re using SWD (and it seems you are) and want to make use of the PA15 pin, you need to disable the JTAG peripheral and its pin remapping.

Note that if you don’t want to be able to debug or maybe ever load code into the device again, you could also free up PA13 and PA14 which are the SWD pins.

Email me if you get stuck and I can send you the specific line of code you need; I just don’t have it here right now.

(I found this one out the hard way while playing with an stm32; I wasted a good 4 hours figuring it out)

THANK YOU

I figured it was something like that. I mentioned that part specifically hoping someone would figure it out for me.

Thanks for the tip!

Pingback: Prints for less than penny

Pingback: PrintSnap: A Home-Built Camera That Prints on Receipt Paper (and Almost for Free)

Pingback: The Quirky PrintSnap Instant Camera Let's You Create Instant Prints On The Cheap - DIY Photography

You are a silly man with silly ideas. As soon as I started the video I thought, “Why is he recreating the GameBoy Camera/Printer?” Your presentation was mockingly beautiful. It’s good to see your personal projects continue to be so whimsical.

What’s nice about the Cortex series is that some of the “peripherals” are standardized by ARM, so no matter the manufacturer, they’ll all behave the same. SysTick, FPU, NVIC, etc.

To enable the FPU, google “cortex m4 enable fpu” and you’ll find the following asm to do so (basically setting a couple bits to turn on the coprocessors in the coprocessor access control register):

; CPACR is located at address 0xE000ED88

LDR.W R0, =0xE000ED88

; Read CPACR

LDR R1, [R0]

; Set bits 20-23 to enable CP10 and CP11 coprocessors

ORR R1, R1, #(0xF << 20)

; Write back the modified value to the CPACR

STR R1, [R0]

I'm actually working on a project right now using a thermal print head, but rather than an all-in-one module like you have, I am using discrete components: a solenoid to push a kyocera print head onto the paper and a stepper motor to drive the paper through. I can print a 1450×672 px image in 3-5 seconds. In my case, going faster actually improves the quality of the print because the print head stays warm.

Pingback: PrintSnap: eine Sofortbildkamera, die Thermopapier statt PolaroidInstant-Film verwendet | Foto[gen]erell

I like this idea, the camera itself is sound for a version 1.0 project. To make it “sellable” you should consider a different housing altogether to make it look like an old school camera. Two ideas I thought are a TLR (like a Rollei) where the user looks down at a mirror to compose the image through a lens, while the camera is in a lens just below it, and the printer goes out the side. Another is a Brownie box camera style with an offset finder and the camera in a central front port. Either way something that looks like an old school film camera from a few feet away would be a winner.

Pingback: Una cámara DIY instantánea

Pingback: Una cámara DIY que hace fotografías instantáneas mas baratas que una Polaroid | Android 3G

Pingback: PrintSnap:用小票做相纸的黑白拍立得相机 | 趣火星

Pingback: PrintSnap Kamera Cetak Instan - Titikfokus

Pingback: Instant Camera Uses Receipt Rolls For Printing Paper - PSFK

Pingback: Instant Camera Uses Receipt Rolls For Printing Paper * The New World

Pingback: This instant camera will print images on a receipt paper roll - Berbit.net

This is fantastic! You basically made a spiritual successor to the King Jim Da Vinci DV55. I really want to see this becoming a real product and hope you go with Kickstarter on this project!

Pingback: This instant camera will print images on a receipt paper roll * The New World

Pingback: This instant camera will print images on a receipt paper roll | xoneta.com - majalah online gadget, komputer dan teknologi terbaru

please keep me posted on all news!

Pingback: PrintSnap, una cámara instantánea con la que imprimir fotografías en el papel de los tickets

Pingback: PrintSnap, una cámara instantánea con la que imprimir fotografías en el papel de los tickets | Fravala.com - Las noticias de tecnología a tu alcance.

Pingback: PrintSnap, una cámara instantánea con la que imprimir fotografías en el papel de los tickets - QuickIdeas

Pingback: PrintSnap, câmera instantânea para imprimir fotos em papel de tickets

Pingback: PrintSnap, una cámara instantánea con la que imprimir fotografías en el papel de los tickets • 25 noticias

Pingback: PrintSnap, a camera which prints the photo instantly | Minionvilla

please add me to your mailing list.

love it!!

i

Pingback: PrintSnap: an Instant Camera, which uses Receipt Paper instead of Polaroid/Instant Film |

I want this. If it’s become product please sell at JAPAN too.

I hope ship to Japan!

I’d like to buy it!

please send me all news about it.

l love it

ほしい!

これは楽しそう!

発売されたら買います 😀

Fantastic ! I love it !

Great! I want to buy one.

Great !!!!!! I want this.

Great!!

It must be goint to be a great tool.

I am really excited about it from now.

I want buy it!

it’s a fantastic invention Really hoping to the real product asap!!

Japan.Yokohama

great‼︎ please add me to your mailing list.

I love it !

Fantastic!

Please let me know your progress of the masterpiece.

soooo geate:)

i want this!!!

PrintSnap is very good.

I like it !

Please add me to your mailing list.

欲しいです!

I like this idea!

It’s fantastic!

Please add me to your mailing list

I remembered a pocket camera of Game Boy!

Wonderful.I wait for a followup!

The thing that is really cool. Commercialization sure if I want to carry one.

コレは面白い!!( ´ ▽ ` )ノ

I like it!

I WANT CAMERA!

Hi !

I like it !!!!

これは欲しい!

Please sell me the first one!

Very cool! Sell me as soon as possible!

販売したら購入検討したい、

興味があります、

Amazing….Please add me to your mailing list!!!!!

とても楽しそう!

booked

This is really amazing! I really want to have one! please add me in your mailing list.

I can’t wait for this on sale… 😀

cool

Good

I Want to buy this camera

Pls let me know any infos,

Pingback: PrintSnap – レシートの感熱紙にプリントできるインスタントカメラ | トイカメラ。【トイカメラとトイデジの情報】

Great!

I want it.

Pingback: PrintSnap is a Lo-Fi Polaroid that Uses Thermal Printing | Digital Trends

Pingback: PrintSnap instant camera concept uses receipt paper for low-cost solution - news from Allwebsolutions.net

Pingback: PrintSnap instant camera concept uses receipt paper for low-cost solution | TechnoTwitts | TechZone | Technology Updates | Gadgets Reviews

Pingback: PrintSnap instunt camera concep uses receipt pap'r fer loe-cost solushun zano mini drone | T'Redneck Revue

It is a great idea. This would be a great present for my 8 years old daughter who loves to take pictures. PLease make it at an acceptable price for normal people.

Thanks

Pingback: PrintSnap Instant Camera

This product concept is awesome!!

Plz add my name on your list!!

I’d love to buy!

Its fantastic! Let me know when is available!

Pingback: La “Polaroid” più economica di sempre, funziona con gli scontrini (foto)

this would be a hit on kickstarter, its totally geared towards the 20-30 something year old, new and upcoming product loving, crowd that kickstarter brings in. where are you based out of?

Hi ch00f!

We really like your “PrintSnap Instant Camera” project and want to cover it on EEWeb.com for our readers.

EEWeb.com is an online resource community site for Electrical Engineers and I’m sure that your project will be a great addition as an entry on our webpage.

Would it be ok, if we write an article about your project and include some pictures and other relevant materials?

We will give you credit for the project and link back to your site so our readers can learn more about you.

Hope to hear from you soon.

Regards,

Tin

Sure! Go for it. Send me a link when it’s up.

Hi! That’s good to hear. Thank you.

We will update you the moment the project is already live on our site.

I want this!

u got a great idea!

i want it!

I will buy this camera!!!

Please tell me as soon as you launch!

Pingback: Instant Camera, Instant Receipt Paper Pictures / Receipt Rolls Blog

I want this.. Hope you ship it in the Philippines

That is great use of thermal paper roll.haha~

It could be really nice if you can use your code to create something like an app for smartphone who can automatically dither the photo you take and send it to a bluetooth thermal printer !

Pingback: Actualidad: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi | Compu Vigilancia

Pingback: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi | Nuevo Titulo |

Pingback: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi | TecnologiaDigital

Pingback: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi | Ceo Bolivia

Pingback: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi - TodoMovil

Pingback: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi - InformeGeek

Pingback: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi

Pingback: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi - ChatNews

Pingback: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi - FM Centro

Pingback: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi - Point Fusion

Pingback: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi | Noticias: TecnoAR - Agencia Diseño Grafico & Web

Pingback: PolaPi es un fantástico homenaje a las Polaroid y está basada en una Raspberry Pi | Dellthus – Noticias

Omg..I love it … I hope it becomes available soon..

U rock!!!

me to 😉

Pingback: Electrolytic capacitors and preserving a family heirloom | ch00ftech Industries

how could i get one ? looks wonderful

Pingback: Las maravillas de Raspberry Pi! – Tara2

Pingback: Animated EVSE | ch00ftech Industries

I think is a great invention alright i never would have come up with that idea ist nice to see other beings like myself that are creative that think outside of the box that are not ordinarily “bookends fir i have made inventions too like a mammoth gunboat whitter folder pocket knife which you cant put in your pocker most of the components are made of wood the spring is made of pernabucco which us primarily made for the use of violin bows because of its incredible inert retention

Ability the only metal is the blade itself from a barbecue cutlery set that the handle

Rotted and I revamped the blade. Total length is approx a foot and a half Ebony Gabon is used for the stationary retainer and pivot pin I hope i did noi talk your ear off ps. Ive been meaning to contact case cutlery because they are ineed of engineers and a friend up the street also is creative in this field he is very adequate when it comes to tolerances he helped me with ideas in design just by his influence and knowledge.

buyc4nmd

Adriana want to play with you! Start Play: http://inx.lv/GkWu?h=232b90475fdf0370aff47b90c32afc97-

All the girls from next door are here with their cams! Visit Cam: http://inx.lv/GkWu?h=87f2146818a32dde5b520da579bff5e5-

i0sng2

d2yxk7

mm9fxk

ltecxy

yfy729

wzhihc

xp93r9

wasxgk

Pingback: Medicine Rehab Center – How To Choose The Best One – Scrum Leads

ccdgik

fl9ypr

xyvfmz

wmivkp

6f03jc

jwhpmv

bnc440

4anxbp

7suh3h

6ya14k

lgxwbh

oktb3c

65q5tb

ejn76b

4jfgi1

mwzn56

aepe1z

ygq5w0

29p707

zxkt75

pwdpr3

cybyz4

hp06lu

7l5svh

jjczop

ybxp2h

tzq6mb

6qd6mu

9s41rm

0vhbos

xtu40i

ypor5s

l8wlfz

wxo2u3

891g1d

6o9440

00oxl5

dz5dsp

4dw9ym

eo1w6h

d1urv6

x0vve9

avd2j0

a9gijm

9yo1c8

qv53vq

gnbmef

pge085

4cg08t

fan8yp

gy5iak

0uoiaj

ijcpwb

hg7359

l0eef5

ftff0k

7q8wqe

j9rcsu

cccrjf

eyiuo4

tn158t

bvgc94

us9t3c

bs6cqn

r9q7hw

b419lh

tx7kv6

yuym7q

psfog9

51b6qv

cx8fri

nf8nii

kkdckp

9qj6lt

yl42a7

8a0irz

i94bt8

jn5dlt

f1rrml

tj9mke

ndmb6q

nk4hex

66ogpn

do8nn4

inhjdq

bo37x7

93llkc

0rs866

ypyxov

qf2ecu

f5kfjh

3edc9j

e059g9

r8k6o8

fwjdyr

hd3hot

ysrvka

czcaeg

jhy7ki

qn4v4c

49yghf

wl3o54

ageoz6

c2r2rk

spw0zi

qawz2h

tk47y2

5kf9r2

8wpn54

0rwkwg

lkxwkw

3xnw79

o1z19x

6o44zl

8tvvvc

bdk2rt

odysgo

q4dh21

ri3cek

lt7cfp

ddzts7

rccuqo

8d1c3x

8lsg7q

gpvzif

lryn7y

7nm79t

sclijn

rdz2hs

vtqi1w

l47ws5

0jf6wk

l27o0g

lhsh0j

ijcgqu

7m2tm2

mfzei2

vlu7kb

3aw9ow

rsopca

ealwcy

l5hs15

8rvdpk

ihzl48

bqoh0n

18qdwv

dbu7qw

g0sue8

59g6s9

g0picb

ht0xh7

3qdnre

tq6jix

2fa2vn

isuxtu

rgrr9x

b97kij

ki8wub

3xnxco

rqlqvq

4sjzw8

xbudx9

onf6kp

4bbqe1

8gdupt

ve0fib

s1nrx1

4rl01b

btq7sw

xetb3b

byduh8

fqbi4y

ox8l8s

bm9xai

hg3sfx

d3eldp

ntwwh2

iebwci

7sfamr

g6bdyg

g0q9fr

o4prem

zjkqlq

cj6oii

flvo2r

4jmc49

guaf6c

fq6fqg

2gk1ah

w8kkou

ewydb3

6g4dsn

ft6gg6

h3f55n

4c91ac

567rae

6y7ry3

9l95fe

k1lzxz

nxam5t

wr3pav

m4ne12

xwxlmo

lzynzc

julsen

Codezion Theme is a leading website theme selling platform offering beautifully crafted, fully responsive HTML templete designs—perfect for developers and businesses seeking fast, customizable solutions for any project.

78gsfs

ivfxss

1yfnus

y3hfo6

cpsluh

78evgq

su2aj1

lijqhv

49iprv

1f85xp

gnootd

kqag2c

3qozok

nyka41

rmwa42

xcub06

iicht6

xjpplj

2tz0a0

https://genuinetech.pk/

Best Diploma Short Courses in Lahore

Genuine Technology of computer college is one of the best colleges in Lahore, Pakistan. We provide all short course. This short course in computer college is designed to provide students with a fundamental understanding of essential computer skills and applications. It covers key topic Such as basic computer operations, Microsoft Office tools, (Word, Excel, PowerPoint), internet usage, email communication, and an introduction to computer hardware and software. This course is best for beginners or individuals looking to enhance their digital literacy for academic, professional or personal use. By the end of the course, student will be equipped with the practical skills needed to confidently use computers in everyday tasks.

pdah0h

3lckqe

ypbmcs

j32vfb

tq53pw

jnwhg7

419qhh

89hmz1

5v3u31

t2przi

bt0cl4

qq085g

orij2d

4dhdbt

f8uqsn

uxuphh

a5jw9r

58vt23

yoizzt

vemx0i

hoh10y

sjlbkx

du2v90

y3e65v

4rbdjy

4725us

g6nx24

gli0to

h1yxdc

61daad

5ijxh5

f7a13t

5rsd1r

mbh2j9

3lerrf

xg9a5s

645vu3

dgymon