So, this is a project that was nearly a month in the making. I set out to make a sound-reactive EL panel but found that driving EL in such a way is actually kind of difficult. If you’ve been following the blog, I’ve been working on this project in one way or another since my transformers article, and it’s actually the reason I wrote that article.

Again, a disclaimer. There are over 8,000 words in this post that document all of my design decisions on this project. It is not a how-to guide, but if you have some background in EE, I hope that you gain something from it.

Without further ado, let’s get down to business.

Update/Disclaimer:

So, it turns out that my electrical model of the EL panel was completely wrong, so this post had to be heavily edited. There are some issues with the design presented here. The circuit being demonstrated in the video above “works”, but not as well as I would like. If you plan on actually creating your own EL panel driver, I recommend reading this post in conjunction with this post.

Otherwise, this post contains tons of useful information on designing and building an H-bridge with a DC-DC switching flyback converter to step 6V up to 120V and drive a 56k

![]()

load. It also contains a few EL panel details that are actually correct. Since writing, I have attempted to remove all of the erroneous information.

If you want to see an EL dimmer that actually works, I recommend starting here.

The Problem With EL

EL materials (wire, tape, panels) are an odd bunch. No matter where you look, EL panels seem to be always be made very cheaply and with very little documentation. There doesn’t seem to be any “pro” version of the stuff.

Also, because it is primarily used in costume design (and not real lighting applications), there are very few Electrical Engineers tackling the issue of powering/controlling it. As a result, you get some hilariously bad attempts at doing cool stuff with EL. My personal favorite is this one where a blogger discovered that blue EL wire turns greenish at lower frequencies. I’ll spare the details of the issues with his design, but this excerpt should tell you everything: “Please note that many audio transformers are potted with a low melting point wax and can get warm enough to leak and fill the holes of your breadboard!” (It’s great that he’s experimenting around, but when that’s one of the better resources out there, that’s a problem for rising hobbyists).

So my goal with this project was to try to exert more sophisticated control over EL materials. So far, everyone can seem to make EL blink fairly easily (like this asshole), but if I know my electronics, fancy gadgets don’t have blinking lights, they have pulsing lights that fade in and out gradually. This is usually because blinking a light is much simpler than dimming one.

So I want to make a dimming EL panel driver. And what the hell, let’s make it react to sound too.

Design

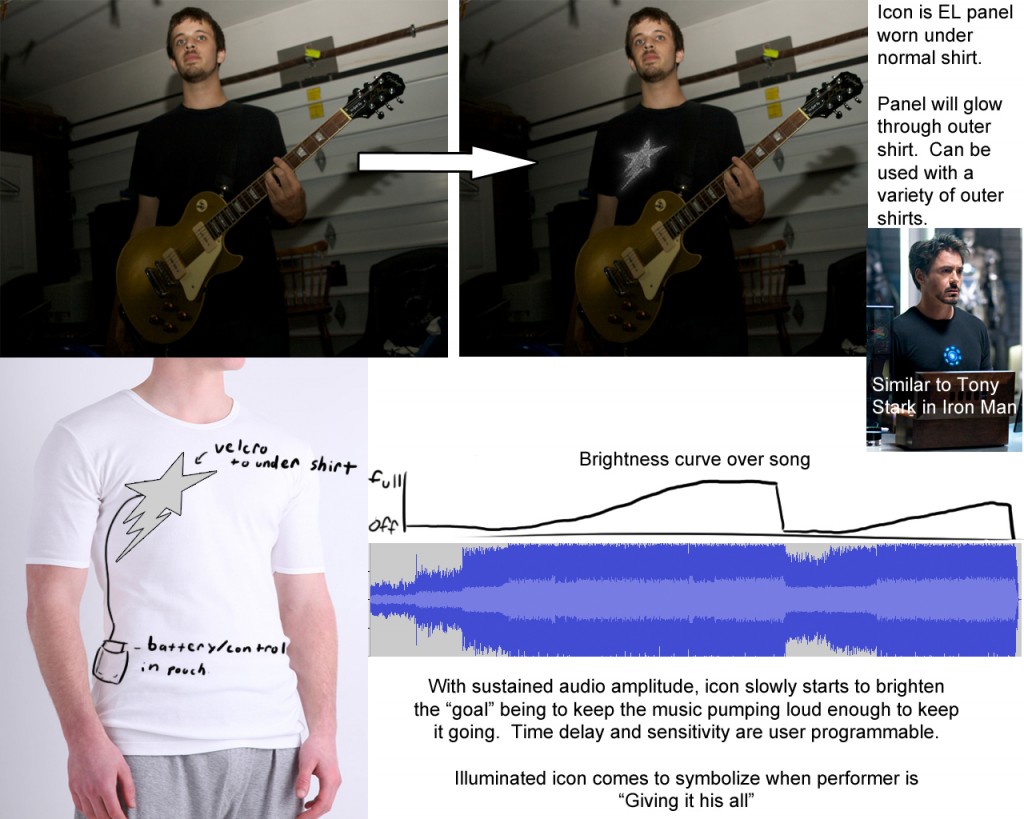

So, this design originally started as a commissioned piece from a guitarist who wanted something cool to wear at concerts. He didn’t have any ideas of his own, so I cooked something up for him:

Basically, the idea was to have an EL panel under his shirt that would pulse and light up to music. All of the “brightness curve over song” stuff ended up flying out the window during the project, but seeing how that would all be controlled by the on board micro controller, it didn’t really matter as I could change it at any point.

So I needed a small battery powered EL panel driver that could pulse and dim the panel by software control.

I purchased this panel. It’s exactly half the size of a standard sheet of printer paper.

Just for fun, I tried plugging the panel into one of my standard EL wire drivers and found that it completely failed to light up. I guess the panel provides too big of a load for the puny wire driver.

Interestingly you can get a faint glow by plugging it straight into a 120V socket.

Electroluminescence

So as you might recall, EL wire is powered by a high voltage (120 or so) AC waveform at a few kHz. Nobody on the internet seems to know exactly how this works. The best that I found was this video by the lovely Jeri Ellsworth (who I might kind of have a crush on at this point). It would seem that the changing of direction of the electric field is what causes the EL to glow. It isn’t exactly important that it gets fed a sine wave; a square wave of similar frequency might also do the trick.

Update:

When I originally wrote this article, I had a long description of what I believed to be the correct electrical model for EL materials. I have since found this model to be wrong and removed it. For the purpose of this discussion, all you need to know is that an EL panel looks sort of like a capacitor. For more details, check out this post.

So, given this information, I would guess that every time the electric field alternates, a small pulse of light is given off. At higher frequencies, more pulses of light are given off in a given time period giving you an overall brighter appearance. The pulse brightness is proportional to the magnitude of the voltage at which you are driving it, but there is a minimum voltage required to get it to light up at all.

But there is a upper threshold on how bright EL can get. Drive at too low a frequency, and you don’t get enough light pulses per second, but drive too fast and its capacitance won’t have a chance to charge up to full voltage. The capacitor voltage will eventually drop below the minimum threshold and your EL won’t light up at all.

I also found this PDF data sheet that confirms this. It isn’t for the EL panel that I purchased, but it should at least give some ideas about EL panels as a whole. On the top of page 3, it says “Brightness increases with higher frequency up to 1000Hz”. This also helped to confirm for me that apparently EL panels don’t get driven at quite as high of frequency as EL wire (1kHz vs 3kHz).

So, it would seem that I simply need to find a way to vary the driving frequency in order to vary the brightness. The only problem is that I also need to keep the voltage of my waveform constant. This complicates things as just about every single EL wire/panel driver circuit out there uses a resonant driver which doesn’t really give you options for variable frequencies.

I could have also just tried using a standard step-up transformer and driving it with a square wave, but this also presented a problem as I would need to have the ability to drop the frequency down to as low as 60Hz. Remember that a transformer is kind of like an inductor which carries the following formula.

![]()

Which can be manipulated to give:

![]()

At lower frequencies (like 60Hz),

![]()

is much larger. To keep the current (

![]()

) from ramping up too much (and making resistive losses a bigger deal),

![]()

must be increased a lot. This will result in a very bulky transformer as you will need a lot of windings and a large core to get a very high inductance.

Because I’ve decided to drive my EL panel with a square wave, there might be a much easier way to do this.

yea there is a MUCH MUCH easier way to do this..

you take the standard inverter and the el panel and put a CDS photocell in series then take a standatd lm328 amplifier and hook the output to a bicolor LED and shine that on the photocell

DONE! i can give you schematics and stuff if you want

So you’re just talking about putting an adjustable resistance in series with the EL panel? I suppose that would work, but it’s not the most efficient way to do it.

Also, looking at a few datasheets, the maximum power dissipation though a CdS cell is around 100mW. If I were to use one on a panel, it might need to dissipate upwards of 7-800mW. It couldn’t take the heat. I suppose you could put a few in series, but that’s going to get pretty messy.

This solution might work in smaller loads like short EL wires though. Thanks for the tip!

When I first read your comment above I thought you were using the photocell to read the light from the EL panel and then reverse the voltage polarity when it detected maximum brightness, which should generate AC that would self-regulate to the right frequency to sustain that brightness level. But then when you mentioned LEDs you lost me! But would a feedback control mechanism like what I thought you meant actually work?

Matthew was recommending using a optoisolator as a variable resistance. The idea is that you could control current from a low-voltage circuit and not have to worry about the 120V blowing anything up.

You present an interesting idea, but I think it would end up being more trouble than it’s worth. The EL panel is a fairly “slow” material. It takes a few milliseconds for it to react to changes in current, so using its brightness in some kind of feedback system would prove difficult. To say nothing of the wiring/mechanical complications this would create.

>> I chose the 1N4148 which has a gate capacitance of just 4pF.

Not gate. Junction.

Since you were ordering from Digi-Key anyway, you could have purchased some BAT-41 Schottky diodes (19,000 in stock) . The BAT-41’s capacitance is 2pF, half of the 1N4148’s capacitance, and its forward voltage at 20mA forward current is 0.30 volts per diode, significantly less than the 1N4148’s 0.95 forward volts per diode.

Whoops, typo. Thanks.

I figured out my diode problem after I already made my order, so I had to use what I had on hand. Next time I’ll be sure to choose more wisely. Thanks for the tip!

while pouring over various patents on zinc sulfide phosphors i discovered reference to the color shift in el wire, my 555 based driver was a quick and dirty means of observing it myself and as an excuse to learn something about driving el wire… more of a first attempt using spare parts before devoting more time to designing a proper circuit rather than basing it off some simple dc to ac inverter circuit i found in the internet

along with the brightness being a function of frequency i found voltage had a similar effect but would cause the el wire to age faster than driving at a higher frequency would, and yes driving at higher voltages also caused my salvaged transformers to overheat and leak paraffin wax everywhere

Oh by all means, I think it’s great what you did, and it really helped me in my initial research! I was just making a point that in general, there aren’t too many resources available on EL wire and driving it properly.

there really arent, i had to resort to reading dozens of white papers and patents to figure everything out, my result was a working driver that was extremely inefficient, occasionally overheated and administered ~130 volt shocks when i wasn’t paying attention

ive also been working out some ideas on mixed frequency driving el wire to increase lifespan while making it brighter by rapidly switching between low and high frequencies at a rate where it would be brighter while impacting lifespan al little as possible

I also noticed the frequency shift.

Wonder if this effect can be used to make a variable spectrum microscope light?

For certain applications this would be handy indeed as if the wavelength shift is linear then you could image a sample at a range of multispectral frequencies rather than green or blue.

I like the Supertex HV852 for this as it draws under 5mA with small wires allowing a PIC to directly drive it and adjust frequency with a single drive lead and a capacitor.

So one 12F683 can run six separate EL wires, with Charlieplexing even more.

as far as i have observed there is only a single color shift at ~2000 hertz and i have not found any information to indicate there any more

it is far from linear and im not sure the amount of light would be sufficient for a microscope anyways

Pingback: Revisiting the EL Panel and the True Meaning of RMS | ch00ftech Industries

Pingback: Naw But Really Though…How Do You Power An EL Panel? | ch00ftech Industries

Pingback: I Should Give China More Credit | ch00ftech Industries

Pingback: The Color Mixing Christmas Light Project » Blog Archive » Pixel Mapping a Jogging Jacket

Pingback: Dimming EL Wire Dreamcatcher | ch00ftech Industries

Pingback: Sound Reactive EL Panel Dimmer (for real this time) | ch00ftech Industries

Pingback: Months of failure lead up to this EL panel dimmer that pulses to the music

Pingback: Months of failure lead up to this EL panel dimmer that pulses to the music | Daily IT News on

Pingback: Can I get this thing off my desk now? | ch00ftech Industries

Pingback: Soil Moisture Sensor | ch00ftech Industries

Pingback: More EL panel / el driver / el inverer hacking – pulsing | Reactive Lights

I found a great source for the EL panels. http://www.etsy.com/shop/lightkraft I looked all over and they are the least expensive in the US.. Most of their prices include the inverters (which are matched to each panel). Another good source is EL-WORKS http://www.el-w.com

Pingback: Bucking It Up » Geko Geek

https://ch00ftech.com/wp-content/uploads/2012/05/flyback11.png

Just saying, #schematicsthatlooklikefaces

What’s your take on this method?

http://www.enactiveenvironments.com/enabling/pwm-and-electroluminescent-smooth-dimming/

Hi,

How can I contact you? Email

Just click the email button at the top of the page!